Mine Waste Dumps Study

For design, operation, monitoring and closure of mine waste dumps and stockpiles, an evaluation of downstream impact from a potential failure by considering the runout hazard area is one of the factors in assessment of the facility consequence and to support decision making on potential mitigation treatments for estimated impacts to downstream infrastructure. Numerical modelling simulation is an effective approach for predicting hazard zones below a mine waste facility. Chen and Cunning (2025) outlined the analysis process and key components to consider, and presented a practical method for forward prediction of potential failure runout zone for a mine waste dump or stockpile facility. A reasonable simulation of the mobilization and runout behaviours can be achieved by considering failure mechanism, using appropriate modelling tools, choosing suitable material rheology and taking account 3D terrainy.

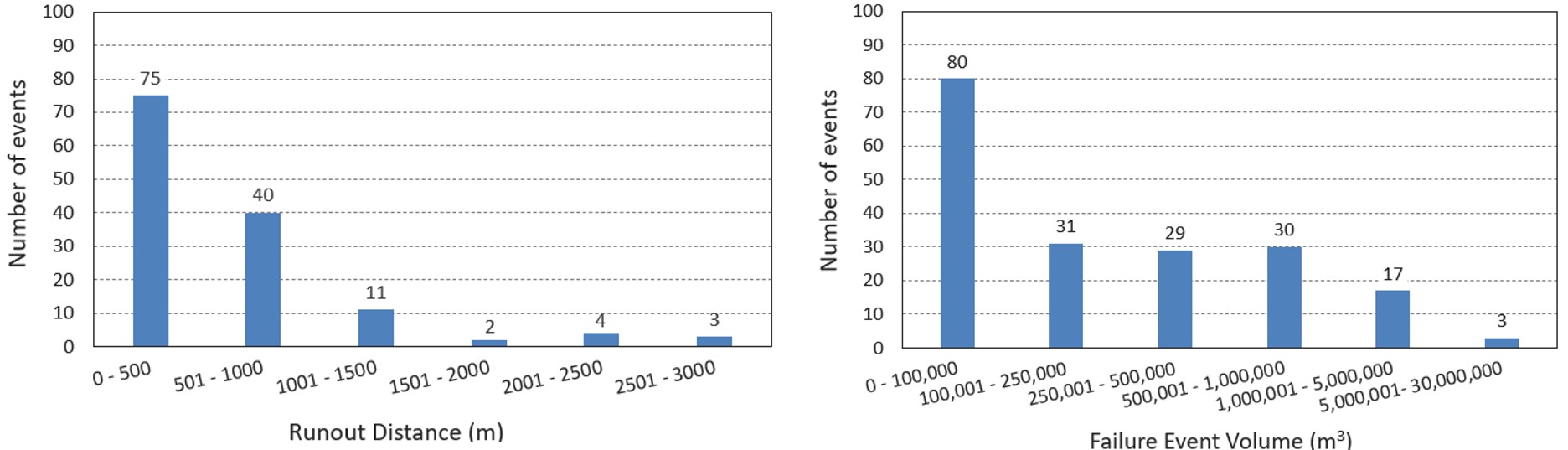

The mine waste in British Columbia, Canada can be end-dumped from large haul trucks, with dump heights ranging from 100’s of metres up to as much as 400 m. While most waste dumps perform well, there are cases where they have been subject to large-scale instabilities with significant adverse consequences. Review (Chen and Cunning 2025) of the data set of runout events up to 2005 shows that most of the failures exhibit runout distance less than 1 km, with a few cases displayed long runout distance of between 2 and 3 km which are considered to have very high mobility. Majority of the failure events are less than one million m3. The combined volume and distance data indicate the need for review of the potential runout zone as part of planning and management of waste dump facilities.

End-dump waste materials are typically deposited in a loose condition and loaded under high shear stress conditions where the angle of repose of the slope face is about 37 to 38 degrees. Characteristic sorting of waste dumps results from segregation of materials during end dumping. When sufficient water (such as from snowmelt or prolonged rainfall) is available and reduces the effective confining stress, this may trigger a collapse. Tests by Dawson et al. (1998) on screened samples of sandy gravel mine waste materials demonstrate that the samples behaved mostly in a strain weakening contractive fashion, and the steady-state condition was not achieved until the axial strains approached 20%. The test results suggest that, when a thickness of these fine-grained layers is sufficient enough and can impede the drainage of pore pressures, collapse can occur after reaching peak strength.

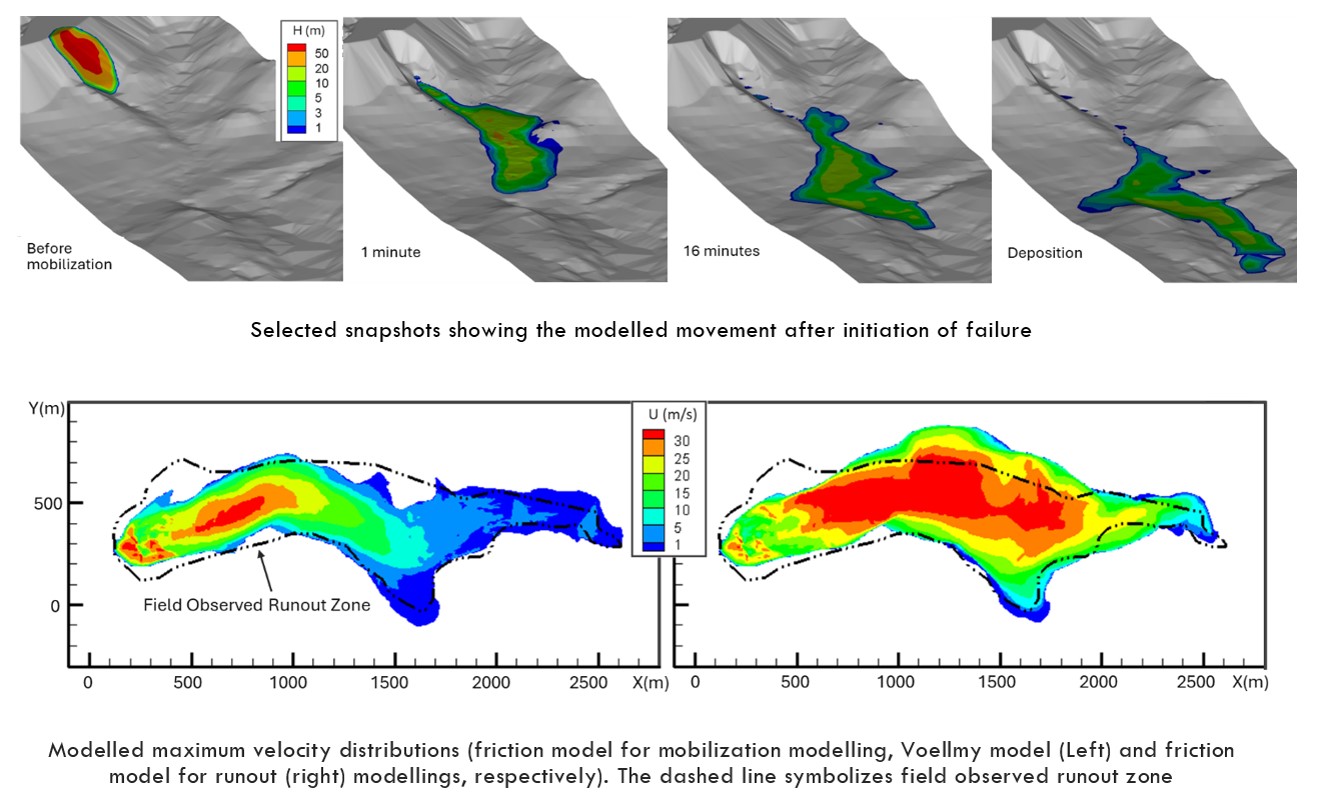

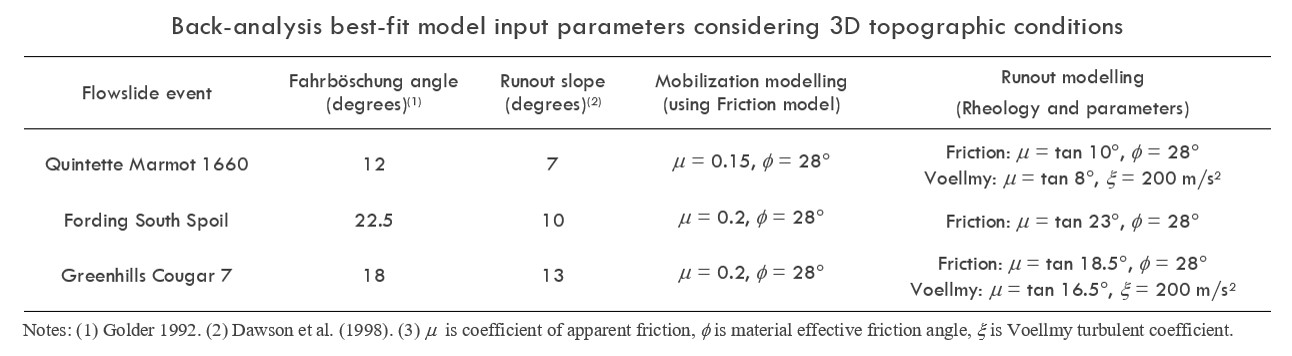

To validate the proposed modelling method, a forensic 3D back-analysis was performed using MADflow from mobilization to runout on three well-documented mine waste dump flowslide failures including the 1985 Quintette Marmot 1660 flowslide, the 1989 Fording South Spoil Stage 1 flowslide, and the 1992 Greenhills Cougar 7 flowslide. Realistic modelling parameters were evaluated in relation to the failure mechanism and measurable parameters from advanced laboratory tests. After the failure was initiated, the flowslide characteristics during runout were found to be more relevant to the properties of the unsaturated, non-liquefiable waste material, geometry and runout path conditions. The model predicted results were found to agree with the available field observations. Friction model is considered suitable for mobilization analysis, where the range of residual undrained shear strength ratio from 0.15 to 0.2 provides a reasonable estimate of the mobilized strength at the onset of collapse. For the subsequent modelling of material propagation, both friction and Voellmy models were found to simulate a (partially) confined valley during most of the runout, though friction model tends to allow more lateral spreading. For runout on open sloping ground (unconfined), frictional model appears more favour.