Tailings Dam Breach Analysis

Tailings dam breach analysis of hypothetical failures supports the evaluation of potential downstream impacts, emergency preparedness and response planning, failure mitigation planning, and mine closure planning. Recognizing the complexity of actual tailings dam breach process, the Canadian Dam Association (CDA) Technical Bulletin - Tailings Dam Breach Analysis (CDA 2021) introduced four conceptual breach cases and a two-process framework for tailings dam breach analysis.

MADflow is capable of simulating the four breach cases (Cases 1A, 1B, 2A, and 2B) with implementation of the novel two-process modelling technique with distinct discharge mechanisms. The eroded tailings surface and volume are numerically modelled with temporal and spatial variations of yield stress, viscosity and specific weight of the flow mixture. Tailings mobilization modelling employs principles of critical state soil mechanics. Major hydrodynamic, geotechnical, rheological, and erodibility considerations related to the tailings hydraulic erosion, tailings mobilization, and inundation modelling are addressed. Moreover, the advanced numerical modelling not only rationalizes tailings dam breach outflow hydrography, but also provides inundation extent and other key parameters, facilitating a reasonable evaluation of the mobility of flowable tailings to support the subsequent assessment of downstream impacts.

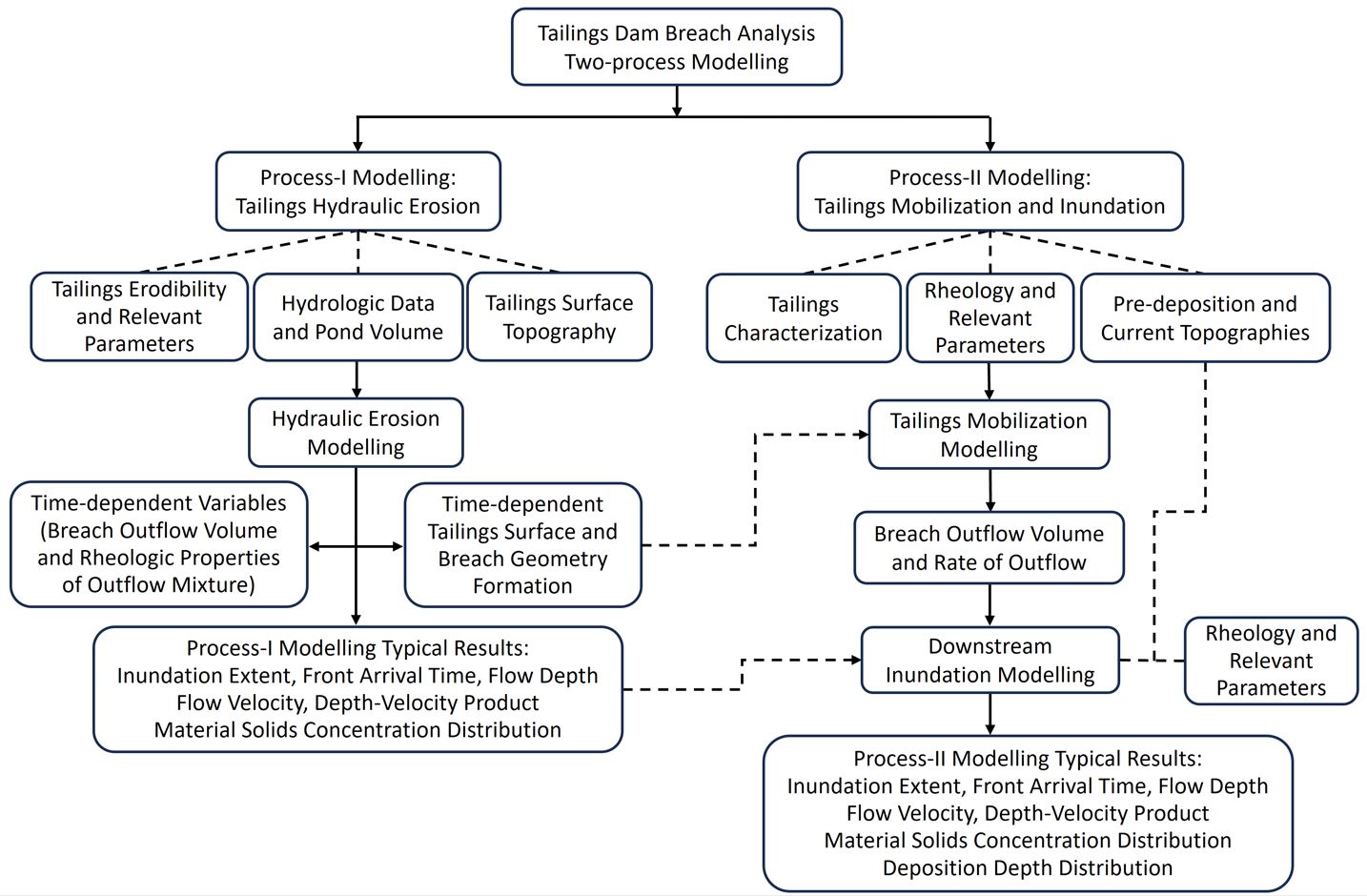

The flow chart below illustrates the two-process modelling workflow and major components. The Process-II modelling can be an independent application to simulate discharge caused by the collapse failure mode.

Process-I involves modelling discharge of supernatant pond carrying eroded tailings and dam fills, treating the outflow mixture as a non-Newtonian fluid with variation of solids concentrations spatially and temporally during erosion (Chen 2022, Chen and Cunning 2025). The modelled breach outflow volume is coupled with the eroded tailings surface and breach geometry formation, erodibilities of the deposited tailings and dam fills, and pond volume.

Following Process-I, using the modelled tailings surface after erosion to avoid double-counting volume across phases, Process-II modelling simulates the remnant tailings as a non-Newtonian fluid from mobilization to inundation (Chen and Cunning 2021, 2025). Rheology and its relevant parameters for tailings mobilization and inundation analyses are not necessarily the same, and sometimes need to be different.

These studies underscore the critical role of tailored numerical simulations, like those facilitated by MADflow, rationalizing the tailings dam breach outflow hydrography and providing accurate prediction of flow behavior and erosion dynamics.